(Las Vegas, Nevada) -- Cement scientist Brent Constantz wants concrete to be the

"hero" that cleans up dirty coal. "The reality is, coal is not going away," he says. "We

need to meet the world’s power demands without emitting more carbon." His answer? A

new type of concrete that sequesters carbon without disturbing its traditional binder:

portland cement.

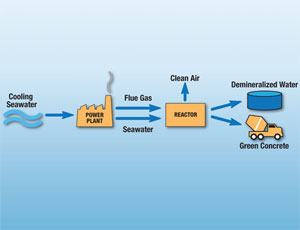

This past summer, the Stanford University professor’s Los Gatos, Calif.-based startup,

Calera Corp., began making cement from flue gas and seawater at Dynegy’s gas-fired

1,500-MW Moss Landing Energy Facility. At first, Constantz hoped to replace portland

cement, which emits about one ton of carbon dioxide per ton produced. But after some

industry pushback and more research, he now says he can use Calera aggregate

synthetic stone, sand and gravel to capture CO2 and still produce net gains.

day of this year’s World of Concrete show speaking to 100 world-leading scientists and

engineers during a 90-minute seminar. In the packed room, Constantz, who owns more

than 70 patents for medical cement, assured the group that Calera could be used to

replace portland though it is not essential. "The way to get it accepted is probably

through the aggregate," he says. (In Las Vegas, Constantz said he can use aggregate

to store carbon in concrete.)

The pitch worked. Florian Barth, a structural engineer and incoming president of

American Concrete Institute, says Calera "has great potential." The seminar "was

promising," adds Steven Kosmatka, vice president of Skokie, Ill.-based Portland

Cement Association. "Although their process needs further refinement…we must keep

a careful watch on Calera," says another scientist who attended.

Unlike cement, aggregate is more voluminous in concrete, making up at least 75% of

the mix. "If we just replace the sand, we get to carbon-neutral," Constantz says. The

new route helps calm fears over using a new, synthetic binder. Kosmatka calls the new

approach a "home run." Barth adds that it could solve other industry problems. "It is

increasingly difficult to get mining permits," he notes.

Calera has gone from 10 employees last year to 100 today and is working on a pilot

plant on the East Coast. By 2010, it plans to have a factory cranking out its calcium and

magnesium carbonate.

Until now, technologies being developed for polluters center on underground carbon

capture and sequestration. CCS could offset 70 years of emissions, perhaps hundreds

more, according to the World Coal Institute. But Calera potentially has no shelf life as

long as the world builds with concrete, trapping up to a half-ton of CO2 in one ton of

material, Constantz says. At full scale, Moss Landing alone could trap 3.4-million tons

per year; that’s like putting over a million hybrids on the road, he adds.

As promising as it is, though, engineers want to see more data. "They have a long way

to go," Kosmatka says. "This is not something that people are going to be ordering next

month."

By Tudor Van Hampton