When the pre historic man constructed a hut for the first time using bamboo trees and coconut leaves to protect himself from sun and rain, he was starting to exploit nature for his humble needs. Apart from killing the trees he also disturbed the natural habital of the insects and birds in those trees and interfered in the cycles of nature. That was a beginning.

Now, it is beyond imagination, how much damage has been inflicted on earth by the construction of various types of buildings using sand and water from the rivers, stones from the mountains, cement manufactured from the ingredients dug from the land. In addition, carbon emission from the buildings and manufacture of construction materials warm up the air and space.

But, after getting conscious about the environment and after feeling the environmental responsibilities, the way our people try to address this problem is wonderful. One of the intelligent initiative is the concept of “Green Buildings”.

The concept of Green Buildings envision a new approach to save water, energy and material resources in the construction and maintenance of the buildings and can reduce or eliminate the adverse impact of buildings on the environment and occupants.

By preferring Green Building over a conventional building we help this planet earth and the people to retain nature to a maximum extent possible in three ways with reference to the location of the buildings.

1. Retain the external environment at the location of the building.

2. Improve internal environment for the occupants

3. Preserve the environment at places far away from the building

Green Buildings Retain the Environment at the location of the Building.

Suppose we propose a multistoried office complex to accommodate thousands of officers and staff, it requires a vast area. Therefore selection of a site for such a building complex should consider retention of local vegetation, wild life, natural water courses etc. Either a site with bio diversity should be avoided or the building should be planned to reduce site disturbance.

Land :The landscaping and the exterior design in a green building shall be in such a way that there is more shaded area, the light trespass is eliminated and local species of plants are grown.

Water : The green building by its design and shape shall not disrupt the natural water flows, it should orient and stand just like a tree. Rain falling over the whole area of the complex shall be harvested in full either to replenish the ground water table in and around the building or to be utilized in the services of the building. The toilets shall be fitted with low flesh fixtures. The plumbing system should have separate lines for drinking and flushing. Grey water from kitchenette, bath and laundry shall be treated and reused for gardening or in cooling towers of air conditioning.

Energy: The solar energy at the top of a green building is harvested to supplement the conventional energy,. The natural light is harvested in the intermediate floors to minimize the usage of electricity. Sunlight is restricted by the high grown trees outside the lower floors of the building. High efficiency light fixtures make a pleasant lighting apart from saving the energy. High-efficiency windows and insulation in walls, ceilings, and floors are used for the benefit of better temperature control.

Green buildings improve internal environment for the occupants

Light: In a designed green building the occupants shall feel as if they are in outdoor location. The interior and exterior designs shall go hand in hand by blending the natural and artificial lighting and presenting transparent views wherever possible.

Air: In the air conditioned environment, a green building shall be specially equipped to ensure the Indoor Air Quality for a healthy atmosphere. Even the nasal feelings shall be pleasant free from the odour of paints and furnishings.

A comfortable atmosphere at work stations improve the attendance of the staff and increase the productivity.

Green buildings preserve the environment at places far away from the buildings.

We all know that a building is constructed using cement, sand, steel, stones, bricks, and a lot of finishing materials. These materials are quarried or procured from far way from the location of the buildings. Building materials are responsible for about 20 percent of the greenhouse gasses emitted by a building during its lifetime,.

Green buildings shall use the products that are non-toxic, reusable, renewable, and/or recyclable wherever possible. Locally manufactured products are prefered so that the collective material environment of the locality remains a constant and moreover the fuel for the transport of materials is saved.

As we see, our food and domestic products are tagged with green as a fashion of eco friendly practices, building materials are also going green. The futuristic green buildings are to use green materials which are in research stage now.

Green wood : A Stanford team has done a research for wood alternate. Hemp fibers and biodegradable plastic when pressed together and heated form layers and this material is as strong as wood. When buried in land fill, it degrades faster. This wood creates more raw materials when it breaks down. Microbes produce methane gas when they decompose this wood substitute and other debris thrown into landfills. Another type of bacteria absorbs this gas and turns it into plastic that can be used to create a new wooden plank. By this cycle, there is a continuous source of raw material for this wood. When this material at research comes to market, it may help to control deforestation and promote the rainfall.

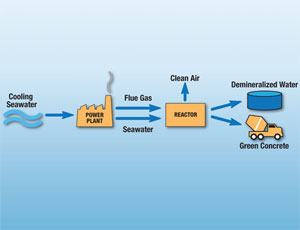

Green Cement: Bruce Constantz at Calera, based in Los Gatos, has developed a green method to produce both cement and aggregate, another component of Concrete. Their method sequesters Carbon Di Oxide from power plant flues and mixes the gas with sea water to produce the mineral raw materials of concrete. For every ton of green cement Calera manufactures half a ton of fly ash from coal plants is used apart from preventing production and emission of Corbon Di Oxide.

Other Green Building materials: Renewable plant materials like bamboo (because bamboo grows quickly) and straw, lumber from forests ecology blocks, dimension stone.recycled stone, recycled metal are some of the other materials used in a Green Building.

LEED GREEN BUILDINGS RATING SYSTEM

The Buildings constructed based on the Green concepts should confirm to the prescribed standards. There should be continuous assessment and and monitoring from the planning/design stage upto the completion of construction, for declaring a building as a Green Building.

For this, LEED ( Leadership in Energy and Environmental Design ) Green Building Rating system is followed. In this system points are awarded for adopting Green concepts in various categories and the Buildings are certified Green at levels such as Silver, Gold or Platinam based on the total number of points they get in LEED Rating.Measurement / Audit for Green Concept in Buildings

Categories for Rating LEED points

Sustainable site 12

Water efficiency 8

Energy and atmosphere 17

Material and resources 13

Indoor Environment Quality 15

Design process and innovation 4

Employing LEED designer 1

Total points 70

Certification for Green Buildings

Level Points required

LEED Certified 26 to 32

Silver Level 33 to 38

Gold Level 40 to 52

Platinam Level 53 and above

There are only few Certified Green Buildings in India. But it is good to know that the awareness is gathering momentum and we look forward for a greener future.

Unpolluted Water, Soil, Mountains and thick Forests

are the Forts defending a Land

( ThiruValluvar 742)

Written by Malarthamil on the eve of observing World Environment Day on June 5